AI Vision Platform

Consulting, Workshops, Implementation, Support

The next generation of

industrial object recognition

Tiliter AI Vision

Imagine a camera that not only sees but understands what you need.

Tiliter AI Vision is the next generation of intelligent object recognition: flexible, scalable and ready to deploy in your production line, sorting facility or logistics operation.

Powered by advanced AI and integrated with ChatGPT, you can simply tell the system via text what it should detect from specific types of plastic to missing components or incorrectly packaged products.

This turns every camera image into actionable data for greater efficiency, fewer errors and full control. Whether as an add-on to existing machines or as a building block for new business models,

Tiliter brings real intelligence to where it’s been missing.

Typical Use Cases

Practical and quick to implement

Typical Use Cases

Practical and quick to implement

Individuelle Bedarfsanalyse und präzise Planung

Recycling & Sorting Technology

Intelligent Sorting for

Clean Material Flows

Tiliter accurately detects and classifies materials from plastics to batteries, reducing manual sorting errors, returns and downtime. Your sorting processes become more efficient, more flexible and significantly more cost effective.

Anpassung und reibungslose Einrichtung

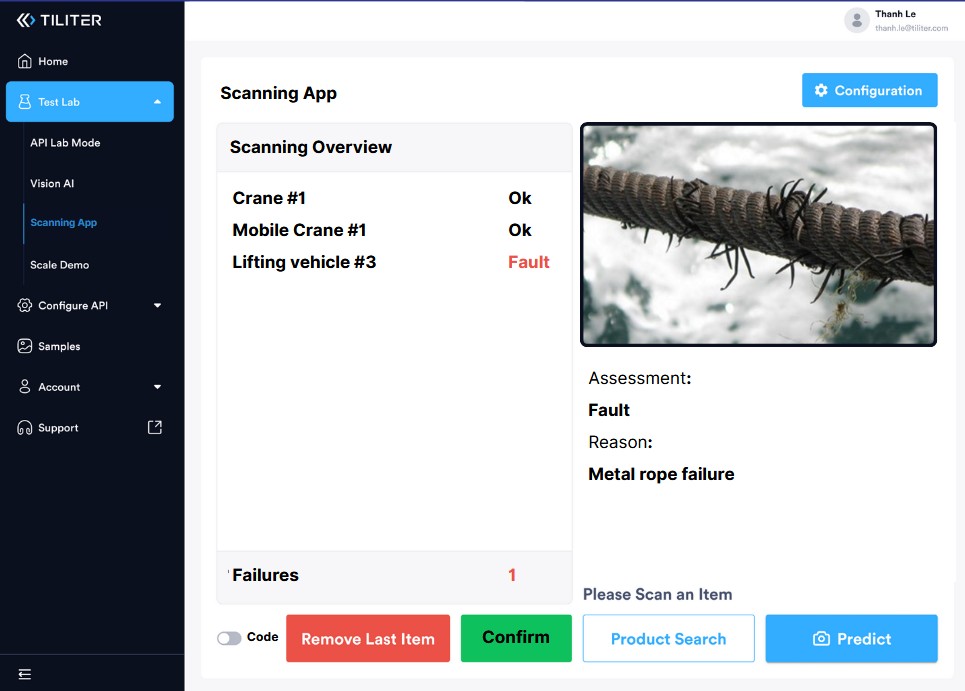

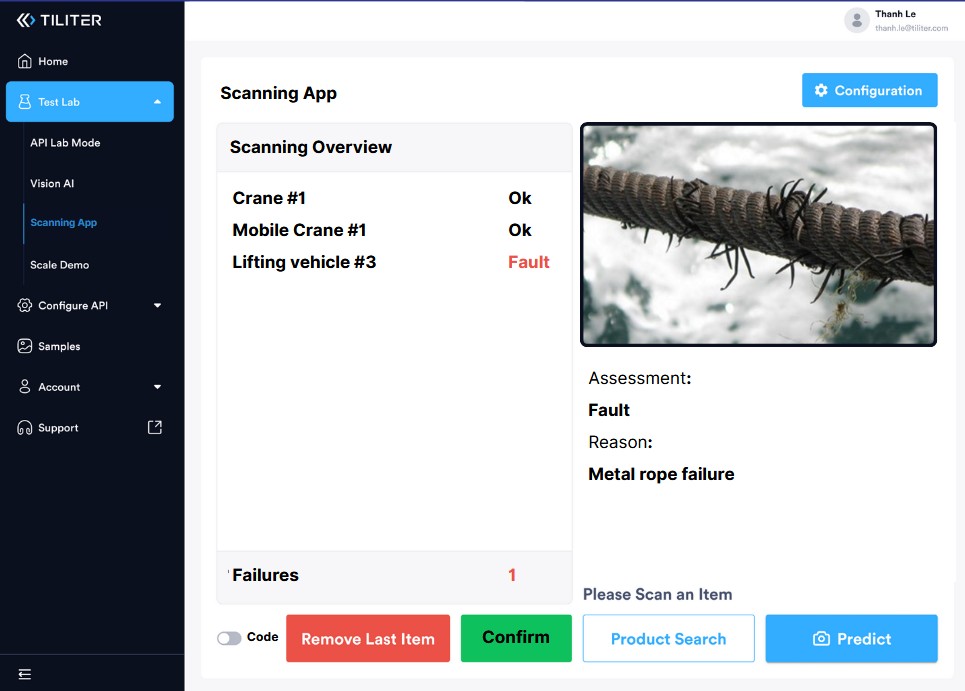

Quality Assurance & Visual Inspection Processes

Intelligent Inspection for

Error Free Products

Tiliter automatically and reliably detects surface defects, missing parts or incorrect variants. This ensures consistent product quality while significantly reducing waste and manual inspection efforts.

Individuelle Bedarfsanalyse und präzise Planung

Production & Manufacturing

More Control in Every

Second of Production

Tiliter monitors components, assembly steps and product variants in real time without the need for special sensors or complex setup. Errors are detected instantly, product changes are managed flexibly, and your line stays stable, efficient and error free.

Anpassung und reibungslose Einrichtung

Maintenance & Safety

Visual Intelligence for

Safe and Stable Operations

Tiliter reliably detects leaks, contamination or missing protective equipment via camera before issues become critical. This increases operational safety, prevents downtime and reduces maintenance costs through early visual diagnostics.

Individuelle Bedarfsanalyse und präzise Planung

Logistics & Packaging

Clear Vision for

Error Free Supply Chains

Tiliter automatically checks packaging, counts units and detects damaged or incorrectly labeled goods. This increases speed and accuracy without the need for manual inspection.

Anpassung und reibungslose Einrichtung

Retail & Point of Sale

Faster Checkout Through

Intelligent Product Recognition

Tiliter automatically recognizes unpackaged goods like fruit, vegetables or baked items without barcodes or manual input. This speeds up checkout, reduces errors at self-service terminals and creates a seamless shopping experience for your customers.

Recycling and Sorting Technology

Tiliter accurately detects and classifies materials from plastics to batteries, reducing manual sorting errors, returns and downtime. Your sorting processes become more efficient, more flexible and significantly more cost effective.

Quality Assurance and Visual Inspection Processes

Tiliter automatically and reliably detects surface defects, missing parts or incorrect variants. This ensures consistent product quality while significantly reducing waste and manual inspection efforts.

Production and Manufacturing

Tiliter monitors components, assembly steps and product variants in real time without the need for special sensors or complex setup. Errors are detected instantly, product changes are managed flexibly, and your line stays stable, efficient and error free.

Maintenance and Safety

Tiliter reliably detects leaks, contamination or missing protective equipment via camera before issues become critical. This increases operational safety, prevents downtime and reduces maintenance costs through early visual diagnostics.

Logistics and Packaging

Tiliter automatically checks packaging, counts units and detects damaged or incorrectly labeled goods. This increases speed and accuracy without the need for manual inspection.

Retail & Point of Sale

Tiliter automatically recognizes unpackaged goods like fruit, vegetables or baked items without barcodes or manual input. This speeds up checkout, reduces errors at self-service terminals and creates a seamless shopping experience for your customers.

What can Tiliter detect?

Tiliter AI Vision detects visually distinguishable objects in real time, flexibly, scalably and without any programming. The software works with standard cameras and can be instantly adapted to new requirements via simple text input.

Typical Use Cases

- Identifying plastics: PET, PE, PP, PLA, mixed materials

- Detecting hazardous items: batteries, spray cans, foreign objects

- Inspecting packaging: counting, damage, labeling

- Checking components: completeness, positioning, variants

- Detecting quality defects: scratches, cracks, damage

- Monitoring safety: leaks, contamination, protective equipment

- Classifying variants: shape, color, size, type

What can Tiliter detect?

Tiliter AI Vision detects visually distinguishable objects in real time, flexibly, scalably and without any programming. The software works with standard cameras and can be instantly adapted to new requirements via simple text input.

Typical Use Cases

- Identifying plastics: PET, PE, PP, PLA, mixed materials

- Detecting hazardous items: batteries, spray cans, foreign objects

- Inspecting packaging: counting, damage, labeling

- Checking components: completeness, positioning, variants

- Detecting quality defects: scratches, cracks, damage

- Monitoring safety: leaks, contamination, protective equipment

- Classifying variants: shape, color, size, type

Custom Analytics for Better Decisions

Tiliter offers a flexible analytics platform that visualizes key metrics and is tailored to your specific processes. This allows you to quickly identify trends, performance deviations and areas for improvement.

Customizable and clear

Dashboards can be individually configured to display exactly the data that matters to you.

Efficiency through data

Use clear insights to make informed decisions and drive targeted process improvements.

More transparency for your business

Complex data is clearly presented and translated into actionable recommendations.

Flexible Integration with Any Camera and System Environment

Tiliter AI Vision can be quickly integrated into existing processes. With a flexible custom API, cameras and systems can be connected with ease.

Camera independent

Tiliter works with standard IP and industrial cameras. Existing USB, network or RTSP hardware can continue to be used.

API integration

The open interface allows direct connection to MES, ERP or SCADA systems. Data flows exactly where it is needed.

Quick start

Setup is straightforward. After a short configuration, the AI immediately delivers actionable results for your processes.

Custom Analytics for Better Decisions

Tiliter offers a flexible analytics platform that visualizes key metrics and is tailored to your specific processes. This allows you to quickly identify trends, performance deviations and areas for improvement.

Customizable and clear

Dashboards can be individually configured to display exactly the data that matters to you.

Efficiency through data

Use clear insights to make informed decisions and drive targeted process improvements.

More transparency for your business

Complex data is clearly presented and translated into actionable recommendations.

Flexible Integration with Any Camera and System Environment

Tiliter AI Vision can be quickly integrated into existing processes. With a flexible custom API, cameras and systems can be connected with ease.

Camera independent

Tiliter works with standard IP and industrial cameras. Existing USB, network or RTSP hardware can continue to be used.

API integration

The open interface allows direct connection to MES, ERP or SCADA systems. Data flows exactly where it is needed.

Quick start

Setup is straightforward. After a short configuration, the AI immediately delivers actionable results for your processes.